DAELMANS

BELLS & TOWER CLOCKS

Stipdonk 16 NL

5715 PC Lierop

tel. +31 (0)492 545 577

tel. +31 (0)6 4606 5621

mail: info@daelmans.com

mail: ralf@daelmans.com

www: www.daelmans.com

Welding monumental bells

Monumental church bells, often seen in church towers, are usually age-old. Everyone in the area recognizes the characteristic sound of these bells; these are individuals and often even named. For generations, these bells have rung at important happenings, from religious heydays to times of misery and everything in between.

During their long existence, these bells have rung tens of thousands of times, which inevitably leads to damage. Fortunately, nowadays the latest technologies are used to repair damage and to bring back the original deep and clear tone of these monumental church bells.

With many years of experience, Toine Daelmans Bells & Tower clocks represents the company Lachenmeyer from Nördlingen , Germany , in the Netherlands . With over eighty years of experience, Lachenmeyer has restored more than 3600 bells worldwide to their original state. Eighty years of quality development has led to restoration into original glory of the following well-known monumental bells.

Bells are removed from

Roman Catholic Church Duistervoorde

Causes of damage

It is often difficult to find out what caused old church bells to crack .

Each and every bell is an individual. Cracks are often caused by one of the following problems:

1. Wrong usage of ringing equipment, a too high angle of the bell when it's struck and heavy-weight clappers.

2. During the years, repeated blows result in weakened areas in the inside rim of the bell and breakdowns at the point of contact.

3. Poor installation maintenance, for example, low-hanging clappers and bells which have loosened from their yoke which may cause side arms to break down.

The advisory committee of the Netherlands Department for Conservation (RDMZ) states:

"Damage to the bell's inner rim may not exceed 10%. It is strongly recommended to weld damaged parts upon this degree of damage.

Seven old-aged bells, together more than 4000 years old,

are ready for welding.

Cracked bell

The damage referred to under 2, has only received the attention it requires since the seventies. Repeated blows of the clapper cause structural metal fatigue on a molecular level. Tension in the material leads to bronze fatigue and increases chances of cracking. Further usage of the bell leads to small cracks becoming one big crack, which may cause dangerous situations. The optic and measurable damage to a church bell therefore only constitutes a small part of the actual damage! Usually, many more hidden cracks, both horizontal and vertical, are discovered after a damaged bell arrives at Lachenmeyer's factory. The damage is usually not visible when the bell is still in the tower; many cracks are hidden. These hidden cracks start from the inside out of the body into the material, after which they are closed by strikes of the clapper. At first, the sound is not affected. The damage only becomes visible after the outer metal layer is polished off. In most cases, damage as mentioned under 1 and 2 appears at the same time, which significantly shortens the church bell's life span.

Bell prepared for welding

New clapper eye

Newly welded bell

During Lachenmeyer's restoration process, refined during decades of experience, the full structure of a monumental church bell is brought back to its original strength. The bell will ring again as the initial bell founders wanted it to ring!

In the Netherlands , Toine Daelmans Bells & Tower clocks has restored approximately 45 damaged bells by welding cracks, broken side arms or damaged inner rims.

Taking apart and assembling the church bells, restoring yokes, bell frames and ringing equipment etc. is done by Toine Daelmans Bells & Tower Clocks and the people he is working with.

Broken crown before restoration

Welded crown

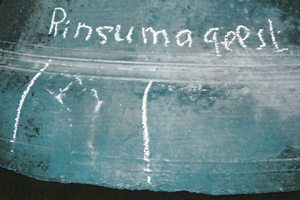

Hoisting at Rinsumageest